Electromagnetic Lifters: Scrap Magnets, Sheet Lifters, and More

Walker electromagnetic lifters are essential tools for industrial material handling, providing secure lifting and transport of ferrous materials through efficient electromagnetic force. From battery-powered units for portable applications to heavy-duty scrap handling systems, these lifters deliver controlled magnetic power for precise material handling across manufacturing, construction, and recycling operations. With features like wireless remote operation and built-in safety sensors, electromagnetic lifters offer reliable performance for demanding industrial environments.

At Tri-State Overhead Crane, we offer a wide range of electromagnetic lifting magnets from Industrial Magnetics Inc., tailored to fit various operational needs. Our lineup includes BUX series battery-powered lifters, scrap handling magnets, and specialized systems for sheet metal and bundle handling, all engineered to meet ASME B30.20 standards. Whether you need portable lifting solutions, heavy-duty scrap handling capabilities, or precise control for cutting table operations, our electromagnetic lifters combine power and control for safe, efficient material handling.

BUXF Flat Surface Magnets

Battery-powered for lifting flat steel like plates and die blocks, ideal for shipping and manufacturing environments. Features smart battery management and ASME B30.20 compliance. Offers user-friendly controls with both push-button and remote operation.

BUXR Round Surface Magnets

Designed for lifting round materials such as pipes, tubing, and bar stock in various industrial settings. Bi-polar design handles a wide range of diameters and thicknesses. Equipped with advanced safety features including bail load sensors for increased reliability.

CER Electro Lift Magnets

Handles heavy steel plates and fabrications with challenging surfaces in demanding applications. Powerful electromagnet with deep field penetration operates on 115-volt AC power. Features onboard and infrared remote controls for safe and efficient operation.

Magnetic Sheet Lifters

Innovative permanent magnetic systems that efficiently de-stack steel sheets from pallets and racks. Their unique design allows a single operator to safely move and load sheets onto cutting tables, shear beds, and other fabrication equipment.

Electromagnet Sweeper

Towable solutions ideal for efficiently picking up unwanted metals from construction sites, airports, dockyards, steel service yards, and more. Their rugged design and powerful magnetic field make them an essential tool for maintaining clean and safe work environments.

Rectangular Scrap Magnet

Designed to lift large volumes of scrap in and out of confined areas. Their powerful deep field design and durable construction make them the standard in melt shops around the world.

ScrapMaster Scrap Magnet

Scrap magnet that features rugged construction to withstand challenging industrial conditions. Their size and power maximize the capture of scrap metal in yards and industrial facilities, ensuring reliable performance day after day.

LiftMaster Scrap Magnet

State-of-the-art, low-cost, and lightweight scrap metal lifting magnets suitable for lighter-duty lifting jobs. Their compact design and efficient operation make them an ideal choice for smaller scrap handling tasks.

Magnetic Tube Lifters

Designed to assist in stacking, destacking, loading, and unloading for tube and pipe applications. These permanent magnets require a simple burst of shop air to release the row of tubes or pipes, making them an efficient solution for material handling.

Bi-Polar Heavy Lift Electromagnet

Ideal for handling bundles of pipe, tubing, rebar, bar stock, plate, structural shapes, castings, forgings, and coiled strips. They lift directly from the center of the load, eliminating the need for additional aisle room to maneuver.

Bundle Magnets

Used for a wide range of applications in all areas of the steel industry. They are frequently used in the production and handling of angles, channels, flats, I-beams, pilings, rebar, rounds, and tubing, offering a versatile solution for material handling.

Total Coverage Magnets

Designed to meet the special material handling needs required in precision flame, plasma, and laser cutting table operations. Their unique design ensures efficient loading and unloading of cutting tables, maximizing productivity.

Rectangular Heavy Lift Electromagnet

Walker's WRL Series are designed to lift plates, slabs, and billets of all sizes. They are commonly found in shipyards, metalworking plants, and service centers, moving large plates to and from cutting tables, fabricating areas, welding departments, and receiving and shipping areas.

Pneumatic-Powered Lifting Magnets

Custom pneumatic lifting devices combine magnetic strength with pneumatic precision, providing tailored solutions for industries like aerospace and heavy equipment manufacturing. Designed to handle non-standard materials, these magnets offer adaptable control for specialized tasks in high-vibration environments.

Permanent Lifting Magnets

Permanent lifting magnets are versatile tools for industries like automotive and construction, designed to lift steel sheets and beams reliably. Available in both electrically controlled and manual options, these low-maintenance magnets enhance versatility for frequent load handling.

Bux Battery Powered Lifting Magnets

Walker's BUX Battery Powered Lifting Magnets offer versatile, cordless lifting solutions ideal for environments without access to traditional power sources. The BUX series includes specialized models like the BUXF for flat materials and BUXR for round surfaces, each designed to meet specific material handling challenges. These magnets combine advanced safety features such as load sensors and dual-button controls with smart battery management, providing reliable operation across shipping, fabrication, and manufacturing environments. Built to ASME B30.20 BTH-1 Category B Service Class 3 standards, BUX magnets deliver efficient, safe lifting capabilities with the convenience of battery power and remote control operation.

BUXF Lift Magnets for Flat Surfaces

- Smart Battery Management - Automatic cut-off prevents over-charging, while an audible alarm and flashing light alert users to low battery levels.

- Safety Features - The magnet will not turn on with insufficient battery charge, and a bail load sensor prevents de-energization while suspended.

- User-Friendly Controls - Features dual push-button release and single push-button lift for efficient operation.

- Convenient Remote - Includes a pocket and belt clip for easy accessibility during use.

- Reliable Design - Built to ASME B30.20 BTH-1 Category B Service Class 3 standards for safety and durability.

- Battery Requirements - Compatible with AGM lead-acid, deep-cycle batteries (not included).

- Applications

- Lifting

- Manual and Hand Lifting

- Below the Hook

- Industries

- Fabrication and Welding

- Steel Production

- Steel Service Distribution

- Automotive Manufacturing

- Appliance Manufacturing

- Equipment Manufacturing

- Furniture Manufacturing

| BUXF Battery Powered Lift Magnet (For Flat Material) |

| Model No. |

WLL (lbs) |

Dimensions (H x L x W) |

Weight (lbs) |

Application/Control |

| BUXF03000 |

3000 |

24-7/8 x 21 x 8-7/8 |

315 |

Battery Powered |

| BUXF05500 |

5500 |

24-7/8 x 21 x 9-5/8 |

371 |

Battery Powered |

| BUXF08000 |

8000 |

25-7/8 x 48 x 9-5/8 |

688 |

Battery Powered |

| BUXF11000 |

11000 |

26-5/8 x 60 x 9-5/8 |

827 |

Battery Powered |

| Custom models or adjustments available upon request. Call (314) 869-7200 or Contact Us for more information. |

BUXR Lift Magnets for Round Surfaces

- Smart Battery Management - Automatic cut-off prevents over-charging, while an audible alarm and flashing light alert users to low battery levels.

- Safety Features - The magnet will not turn on with insufficient battery charge, and a bail load sensor prevents de-energization while suspended.

- User-Friendly Controls - Features dual push-button release and single push-button lift for efficient operation.

- Convenient Remote - Includes a pocket and belt clip for easy accessibility during use.

- Reliable Design - Built to ASME B30.20 BTH-1 Category B Service Class 3 standards for safety and durability.

- Battery Requirements - Compatible with AGM lead-acid, deep-cycle batteries (not included).

- Applications

- Lifting

- Manual and Hand Lifting

- Below the Hook

- Industries

- Fabrication and Welding

- Steel Production

- Steel Service Distribution

- Automotive Manufacturing

- Appliance Manufacturing

- Equipment Manufacturing

- Furniture Manufacturing

| BUXR Battery Lift Magnet (For Flat, Round or Shaped Material) |

| Model No. |

WLL (lbs) Plate/Rounds |

Dimensions (H x L x W) |

Weight (lbs) |

Application/Control |

| BUXR01665 |

1665/1665 |

30-1/8 x 21 x 9-1/2 |

461 |

Battery Powered |

| BUXR03330 |

3330/3330 |

32-1/2 x 30 x 10-1/2 |

821 |

Battery Powered |

| Custom models or adjustments available upon request. Call (314) 869-7200 or Contact Us for more information. |

CER Series Electro Lift Magnets

- Versatile Control Options - Features onboard operational controls and an infrared remote with a range of up to 15 feet.

- Convenient Power Input - Operates with a standard 115-volt AC input and includes male/female connectors for easy setup.

- Self-Sufficient Design - Requires no external power supply during operation.

- Built for Safety - Complies with ASME B30.20 BTH-1 Category B Service Class 3 standards for reliable performance.

- Applications

- Lifting

- Manual and Hand Lifting

- Below the Hook

- Industries

- Fabrication and Welding

- Steel Production

- Steel Service Distribution

- Automotive Manufacturing

- Appliance Manufacturing

- Equipment Manufacturing

- Furniture Manufacturing

| CER Electric Lift Magnet |

| Model No. |

WLL (lbs) |

Dimensions (H x L x W) |

Weight (lbs) |

Watts (115/1/60 supply) |

| CER05 |

600 |

11-1/4 x 5-1/8 x 5-1/8 |

21 |

92 |

| CER07 |

1200 |

11-1/4 x 6-3/4 x 6-3/4 |

41 |

135 |

| CER09 |

2400 |

11-3/4 x 9 x 9 |

90 |

208 |

| CER12 |

4000 |

13-5/8 x 12 x 12 |

140 |

420 |

| CER16 |

7250 |

19-1/2 x 16 x 16 |

340 |

495 |

| CER20 |

10500 |

15 x 20 x 20 |

575 |

1050 |

| Custom models or adjustments available upon request. Call (314) 869-7200 or Contact Us for more information. |

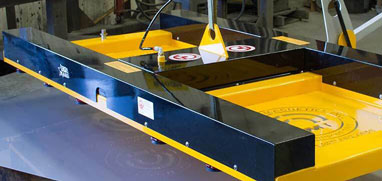

Magnetic Sheet Lifting Systems

Walker's Magnetic Sheet Lifters are innovative permanent magnetic systems that efficiently de-stack steel sheets from pallets and racks. Their unique design features adjustable position magnetic lifting heads to accommodate a wide variety of sheet lengths and widths, enabling a single operator to safely move and load sheets onto cutting tables, shear beds, and other fabrication equipment. These systems incorporate push-button pneumatic controls for precise activation of the magnetic heads, offering quick attachment and release while maintaining fail-safe operation. The Sheet Lifting Systems excel in manufacturing, steel processing, and fabrication environments where efficient sheet handling is critical to productivity.

Magnetic Sheet Lifters

- Versatile Sheet Handling - Accommodates virtually any size and thickness of steel sheet.

- Enhanced Thin Material Performance - Specialized design ensures excellent lifting of thin sheets.

- Simple Pneumatic Operation - Functions with standard 85 PSI shop air for easy integration.

- Quick-Action Control - Single air burst enables instant grip or release for efficient operation.

- Permanent Magnet Reliability - Combines permanent magnet dependability with electromagnet-like control.

- Failsafe Protection - Maintains grip during power or air system failures without battery backup.

- Single-Pass Efficiency - Capable of complete cutting table clearance in one operation.

- Thermal Management - Operates without heat buildup for continuous use.

- Energy Efficient - No constant power requirement for magnetic hold.

- Applications

- Below-the-Hook

- Manual and Hand Lifting

- Lifting

- Magnetic Transfer

- Magnetic Parts and Sheets Separation

- Magnetic Stacking and De-Stacking

- Industries

- Automotive Manufacturing

- Steel Production

- Steel Service Distribution

Scrap Magnet

Walker's Scrap Magnet series delivers powerful electromagnetic solutions for diverse scrap handling operations, from yard cleanup to melt shop material handling. The comprehensive lineup includes Electromagnet Sweepers, Rectangular Scrap Magnets, ScrapMaster, and LiftMaster models, each engineered for specific scrap handling challenges. Built with features like rugged ribbed cases, heavy-duty manganese bottom plates, and watertight construction, these magnets ensure reliable performance in demanding environments. Operating at a 75% duty cycle and available with both aluminum and copper coil options, Walker scrap magnets provide the durability and lifting power needed for efficient scrap processing operations.

Electromagnet Sweeper

- Versatile Towing Options - Equipped with pneumatic tires and an adjustable towbar for easy transport.

- Convenient Parking - Features a built-in parking stand for secure storage when not in use.

- Reliable Power Supply - Includes a 115-volt AC generator for consistent performance.

- Durable Engine - Powered by a robust 4-stroke OHV gasoline engine for long-lasting operation.

- Wide Application Range - Suitable for use in various industries, including mining, energy, and utilities.

- Applications

- Industries

- Mining and Aggregate

- Energy and Utility

Rectangular Scrap Magnet

- High Duty Cycle - Operates at a 75% duty cycle for extended periods of use.

- Heavy-Duty Construction - All-welded design ensures long-lasting performance in demanding environments.

- Cool Operation - Maintains optimal operating temperatures for consistent lifting power.

- Superior Insulation - Class H insulation provides excellent protection against electrical and thermal stresses.

- Deep Field Design - Generates a powerful magnetic field for efficient scrap lifting.

- Coil Options - Available with aluminum coils (standard) or copper coils (optional) to suit specific requirements.

- Easy Maintenance - Quick-disconnect lead assembly simplifies maintenance and repair processes.

- Voltage Versatility - Offered in 230 VDC, 230/180 VDC, and 230/140 VDC configurations to match power supply needs.

- Applications

- Recycling Product

- Metal Separation and Sorting

- Industries

- Scrap Recycling

- Construction and Demolition

ScrapMaster Scrap Magnet

- Durable Housing - Rugged cast steel case protects the magnet from harsh environments.

- Extended Operation - 75% duty cycle allows for prolonged use without overheating.

- Powerful Magnetic Field - Deep field aluminum wound coil generates strong lifting power.

- Maximum Lift Performance - Designed to maintain optimal lifting capacity throughout the working day.

- Superior Insulation - Class H insulation provides excellent protection for layer-to-layer, turn-to-turn, and coil-to-case insulation.

- Reduced Maintenance Costs - Durable construction minimizes the need for frequent repairs and maintenance.

- Heavy-Duty Chain - Alloy steel chains offer greater life and maximum durability.

- Voltage Options - Available in dual voltage models to accommodate different power supply requirements.

- Customizable Designs - Can be customized in fabricated styles to suit specific application needs.

- Optional Copper Coil - Optimal copper wound coil available for enhanced performance.

- Applications

- Recycling Product

- Metal Separation and Sorting

- Industries

- Scrap Recycling

- Construction and Demolition

LiftMaster Scrap Magnet

- High Duty Cycle - Operates at a 75% duty cycle for extended periods of use.

- Deep Field Construction - Generates a strong magnetic field for effective scrap lifting.

- Durable Chain - Three-leg alloy steel chain provides long-lasting strength and reliability.

- Rugged Case Design - Low carbon, high permeable steel case maximizes lifting efficiency.

- Lightweight Coil - Aluminum wound coil offers an excellent lift-to-weight ratio.

- Standard Voltage - Operates on 230 volts DC for compatibility with common power supplies.

- Superior Insulation - All Class H insulation ensures excellent protection against electrical and thermal stresses.

- Encapsulated Coils - Coils are encapsulated in a high dielectric strength, moisture-resistant, resilient compound for added durability.

- Heavy-Duty Bottom Plate - Heavy rolled manganese bottom plate provides structural strength and stability.

- Abrasion-Resistant Poles - Inner and outer pole surfaces are hard-faced with an abrasive-resistant layer of weld to retard wear.

- Applications

- Recycling Product

- Metal Separation and Sorting

- Industries

- Scrap Recycling

- Construction and Demolition

Tubes and Bundles

Walker's Tube and Bundle Magnets provide comprehensive solutions for handling bundles of pipe, tubing, rebar, and structural shapes across the steel industry. The range includes specialized Magnetic Tube Lifters and versatile Bundle Magnets, designed to handle materials efficiently while reducing dunnage costs and manpower requirements. These magnets feature deep field designs, copper wound coils, and Class H insulation, available in multiple duty cycle options to match specific operational needs. Compatible with fixed, rotating, and expandable beams, these systems deliver reliable performance in steel mills, metal working facilities, and service centers.

Magnetic Tube Lifters

- Simple Operation - Requires only a burst of air to grip or release the load.

- Versatile Compatibility - Works on round, square, and custom-shaped tubing.

- Standard Air Supply - Operates on readily available 85 PSI shop air.

- Nested Tube Handling - Capable of destacking nested tubing for improved efficiency.

- Reduced Cycle Times - Significantly reduces cycle times in many tube handling applications.

- Failsafe Design - Maintains a secure grip on the load even during power or air system failures, without the need for a battery backup.

- Powerful Magnetic Circuit - Utilizes a powerful, rare earth magnetic circuit for strong lifting capacity.

- Durable Construction - Features a stainless steel housing for long-lasting performance.

- Customizable Options - Available with custom cylinders, magnetic circuits, and pick-up points to suit specific application requirements.

- Protective Covers - Optional protective magnet covers available for handling polished, plated, or painted tubing.

- Applications

- Lifting

- Manual and Hand Lifting

- Below the Hook

- Industries

- Steel Production

- Steel Service Distribution

Bi-Polar Heavy Lift Electromagnet

- Efficient Bundle Handling - Handle bundles quickly and reduce cycle times.

- Cost Reduction - Minimize dunnage costs through optimized stacking.

- Manpower Optimization - Reduce the number of operators required for material handling.

- Increased Storage Capacity - Stack loads as high as the crane allows, maximizing storage space.

- Enhanced Safety - Create a safer working environment by reducing manual handling.

- Versatile Beam Compatibility - Can be used with fixed beams, rotating beams, and expandable beams.

- Deep Field Design - Concentrates the magnetic field to prevent attraction of adjacent materials.

- Customizable Pole Shoes - Available with special pole shoes for specific applications.

- Complete System Engineering - Supplied with power supply, controls, battery backup, and spreader beams.

- Applications

- Below-the-Hook

- Magnetic Transfer

- Industries

- Steel Production

- Steel Service Distribution

- Construction and Demolition

- Equipment Manufacturing

- Fabrication and Welding

Bundle Magnets

- Faster Bundle Handling - Enables quicker handling of bundles, reducing cycle times.

- Reduced Dunnage Costs - Minimizes the need for dunnage materials, resulting in cost savings.

- Manpower Optimization - Reduces the number of operators required for bundle handling tasks.

- Increased Storage Capacity - Allows for more efficient storage of bundles, maximizing available space.

- Enhanced Safety - Creates a safer working environment by minimizing manual handling of heavy bundles.

- Beam Compatibility - Can be used with fixed beams, rotating beams, and expandable beams for versatile installation options.

- Deep Field Designs - Generates strong, deep magnetic fields for secure lifting of bundles.

- Copper Wound Coils - Features copper wound coils for optimal lifting performance.

- Superior Insulation - Utilizes Class H insulation for excellent protection against electrical and thermal stresses.

- Duty Cycle Options - Available in 50%, 75%, or 100% duty cycles to match application requirements.

- Hot Work Designs - Offers hot work designs for use in high-temperature environments.

- Customizable Pole Shoes - Can be fitted with customized pole shoes to maximize magnetic efficiency for specific applications.

- Applications

- Angles

- Channels

- Flats

- Pilings

- Tubing

- Rounds

- Rebar

- I-Beams

- Industries

- Steel Mills

- Metal Working

- Service Centers

- Warehouses

- Shipping and Receiving

- Fabricating Areas

- Shipyards

Cutting Table Loading/Clearing

Walker's Total Coverage Magnets are engineered specifically for precision flame, plasma, and laser cutting table operations. These specialized systems streamline the process of loading plates and unloading cut parts, enabling efficient handling of materials ranging from 3/16" to 1 3/4" thick. Available in custom sizes to match specific cutting table dimensions, these magnets eliminate time-consuming manual handling methods and reduce idle machine time. The Total Coverage series optimizes cutting table productivity while ensuring safe, efficient material handling in precision cutting environments.

Total Coverage Magnets

- Versatile Plate Handling - Capable of handling plates from 3/16″ to 1 3/4″ thick, accommodating a wide range of material thicknesses.

- Small Part Unloading - Efficiently unloads parts as small as 6″ x 6″, ensuring complete table clearance.

- Customizable Sizes - Available in custom sizes to fit specific cutting table dimensions and requirements.

- Reduced Manual Labor - Minimizes the need for manual handling of plates and cut parts, enhancing operator safety and efficiency.

- Increased Cutting Table Utilization - Enables faster loading and unloading of cutting tables, maximizing machine uptime.

- Improved Cut Part Quality - Reduces the risk of part damage during handling, ensuring high-quality finished products.

- Enhanced Operator Safety - Eliminates the need for operators to manually handle heavy plates and sharp cut parts, reducing the risk of injuries.

- Seamless Integration - Designed to integrate seamlessly with existing cutting table systems for easy installation and operation.

- Durable Construction - Built with robust materials and components to withstand the demanding conditions of cutting table environments.

- Applications

- Below-the-Hook

- Magnetic Transfer

- Industries

- Steel Production

- Steel Service Distribution

- Construction and Demolition

- Equipment Manufacturing

- Fabrication and Welding

Heavy Plate Handling

Walker's Heavy Plate Handling Magnets excel in moving plates, slabs, and billets across shipyards, metalworking plants, and service centers. The series includes Rectangular Heavy Lift Electromagnets designed with robust features like copper wound coils, Class "H" insulation, and waterproof components. Available in multiple duty cycle options and voltage configurations, these magnets can be integrated with various suspension systems including standard beams, telescopic beams, and tilting systems. Each magnet can be supplied as part of a complete system with power supplies, controllers, remote systems, and safety features, ensuring optimal performance in demanding material handling applications.

Rectangular Heavy Lift Electromagnet

- Versatile Lifting Capabilities - Handles single plates (de-stacking), multiple plates, and hot plates.

- Flexible Suspension Options - Available with standard beams, telescopic beams, and tilting systems.

- Robust Construction - Fully welded heavy-duty magnet case for durability.

- Efficient Coil Design - Copper wound coils and Class "H" insulation for optimal performance.

- Adjustable Duty Cycles - Available in 50%, 75%, and 100% duty cycles to suit application needs.

- Enhanced Safety Features - Waterproof outlet box, lead cables, and optional wireless or wired controls.

- Flux Enhancement - Pole configurations designed to maximize lifting efficiency.

- Voltage Options - Available in 115 or 230 VDC to match power supply requirements.

- Customizable System Integration - Can be supplied with spreader beams, power supplies, controllers, remote systems, and battery backup.

- Applications

- Below-the-Hook

- Magnetic Transfer

- Industries

- Steel Production

- Steel Service Distribution

- Construction and Demolition

- Equipment Manufacturing

- Fabrication and Welding

Electromagnetic Lifting Magnets Documents

TSOC has the experience and engineering to design and manufacture your next electromagnetic lifter and below the hook lifting device. We serve clients from coast to coast, Canada, Mexico and are especially focused in Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.